6/12V (Vertical)

The Babyplast 6/12V (Vertical) injection molding machine excels in delivering unparalleled precision, thanks to its innovative combination of piston injection and pre-plastification. This dual approach ensures that each injection cycle is meticulously controlled, resulting in consistently high-quality parts. What sets this machine apart is its adaptability; with eight different piston diameters available, it allows for the precise optimization of shot weights, accommodating a diverse range of part sizes and weights. This flexibility makes the Babyplast ideal for producing small to medium-sized plastic components, especially in industries where precision is paramount.

Features

“Production Ready”

A common misconception is that the Babyplast machine is not suited for production environments. This is simply not true. In fact, 85% of Babyplast customers use the machines in production, taking advantage of its compact design and the significant savings it offers in tooling costs and energy consumption.

Precision

The Babyplast 6/12V offers unmatched precision with its cutting-edge injection piston and advanced pre-plastification system. This state-of-the-art technology delivers meticulous accuracy in every detail. Its versatility enables precise customization, ensuring optimal performance and consistency in every molding process. With the Babyplast 6/12, you can count on exceptional quality and precision, making it a top choice in the injection molding industry.

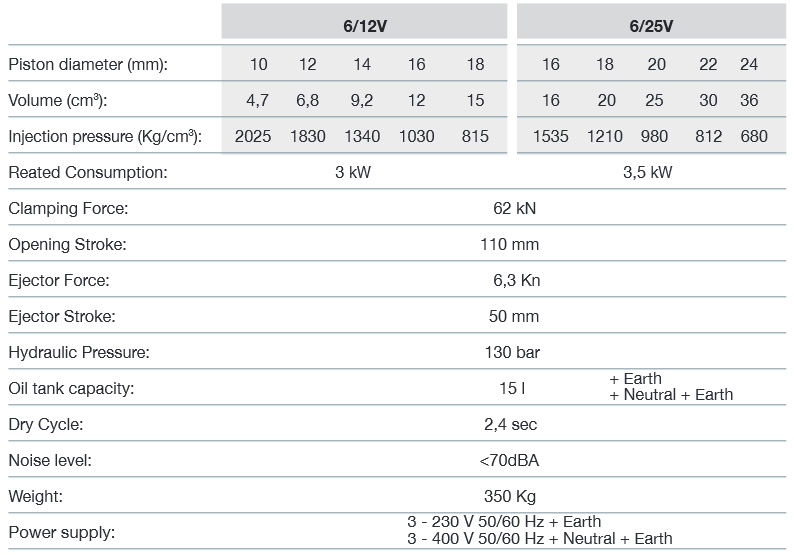

Specifications & Technical Data

- Clamp without tie bars

- Backlit 8″ touch screen LCD

- Various different languages can be selected

- Easily accessible pages thanks to multi-function keys

- Quality Control on main cycle parameters

- PID temperature control (up to 420°C)

- 5 temperature control zones, of which two are available for mould temperature control or hot runner 230 V

- Manages and stores over 1000 production cycles

- Program back-up USB output

- Ethernet Connection : TCP modbus

- Pressure control with electronic transducer

- Injection position control and closure with linear transducers

- Proportional hydraulics

- Very quiet motor pump controlled by an inverter

- Euromap 67 (optional)

- 3 different configurations: standard, rotary table and V-table

- Low running costs – installed power 3 kW – cooling approximately 120 l/h

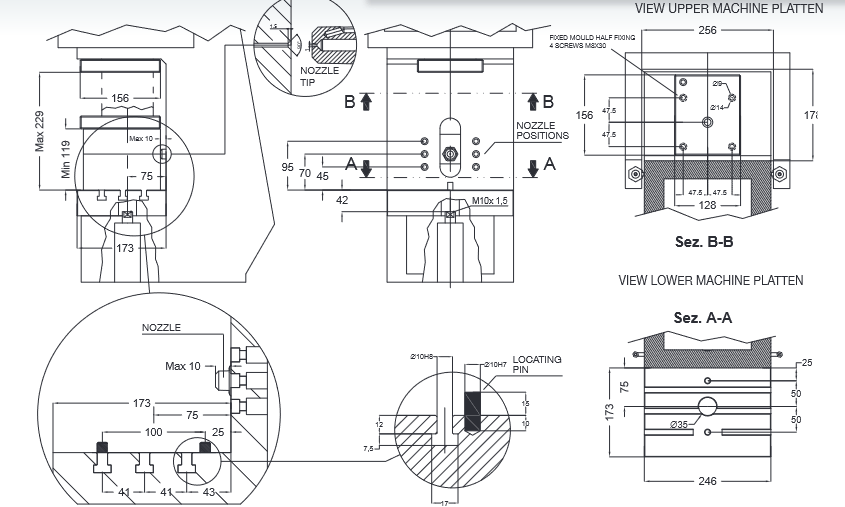

- 3 different injection positions

- 2 injection units: standard (max 15cc) – Plus (max36cc) with 5 different injection piston diameters

- Output for auxiliary control

- Cooling circuit (6 zones)

- Temperature tolerance band

- Hydraulic ejection with ejector return sensor

- Air blow and core pull