Advanced Control and Interface

This state-of-the-art clamping system features a clamp without tie bars, providing enhanced accessibility and functionality. The user interface is highlighted by a backlit 8″ touch screen LCD that supports multiple languages, ensuring ease of use for operators worldwide. Navigation is made simple with multi-function keys, allowing users to access various pages effortlessly. Quality control is integrated into the main cycle parameters, offering precise oversight, while PID temperature control can reach up to 420°C. The system boasts five temperature control zones, two of which are dedicated to mould temperature control or hot runner at 230 V.

Features

High-Efficiency Operation

Efficiency and precision are at the core of this system. It can manage and store over 1000 production cycles, with program back-up facilitated via USB output. Connectivity is robust, featuring an Ethernet connection with TCP modbus support. Pressure and injection position control are finely tuned with electronic and linear transducers, respectively. The proportional hydraulics and a very quiet motor pump, controlled by an inverter, ensure smooth and efficient operations. The system is compatible with Euromap 67 as an optional feature, enhancing its flexibility and integration capabilities.

Versatile Configurations and Features

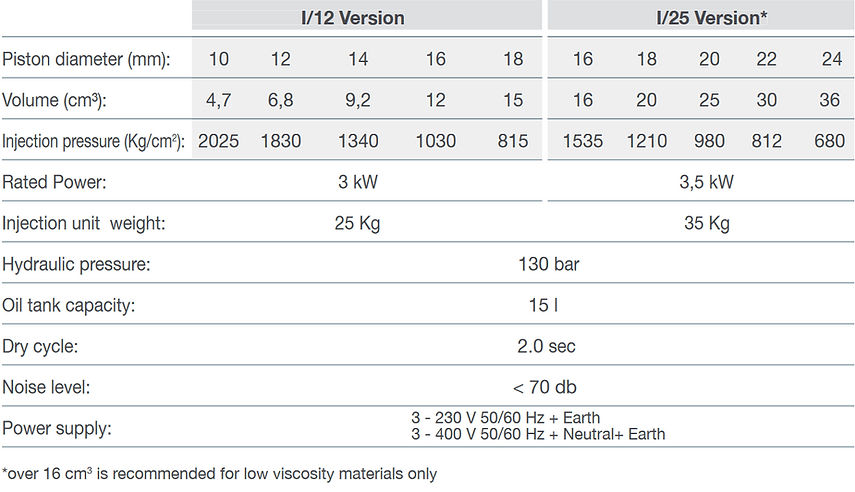

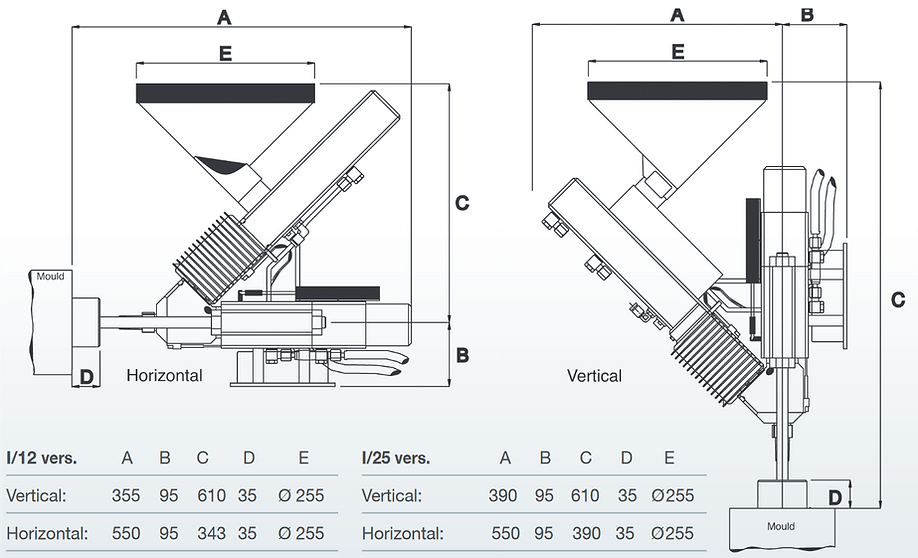

The clamping system offers three different configurations: standard, rotary table, and V-table, catering to various production needs. Its low running costs are a significant advantage, with an installed power of 3 kW and a cooling requirement of approximately 120 l/h. It supports three different injection positions and two injection units: standard (max 15cc) and Plus (max 36cc) with five different injection piston diameters. Additional features include an output for auxiliary control, a cooling circuit with six zones, a temperature tolerance band, hydraulic ejection with an ejector return sensor, air blow, and core pull functions.

Specifications & Technical Data

- Backlit 8″ touch screen LCD

- 10 different languages can be selected

- Easily accessible pages thanks to multi-function buttons

- Removable keyboard

- Quality Control on 4 cycle parameters

- PID temperature control (up to 420°C)

- 4 PID temperature control zones, one of which is free for auxiliaries (hot chamber)

- Injection carriage movement

- I/O interface with voltage free contacts

- Manages and stores over 1000 production cycles

- Program back-up USB output

- Ethernet Connection : TCP modbus

- Pressure control with electronic transducer

- Injection position control with linear transducer

- Proportional hydraulics

- Very quiet motor pump controlled by an inverter

- Control output for shutter nozzles

- Expansion Card to check the sequential shutter nozzles (optional)

- Low running costs – installed power 3 kW – cooling approximately 120 l/h

- 2 injection groups:

- STANDARD 5 pistons of 3 to 15 cm2 with 2650 to 815 bar

- PLUS 5 pistons of 16 to 36 cm2 with 1535 to 680 bar

- Output for auxiliary control

- Cooling circuit

- Temperature tolerance band

- Air blow and jack control