Liquid Silicon Rubber ‘Ready’

Injection molding with the Baybplast LSR is a specialized process used to manufacture high-quality, durable, and flexible parts. LSR is a two-component material that is injected into a mold to create detailed and complex shapes. Injection molding with Babyplast LSR is a highly efficient and versatile process, ideal for producing complex, durable, and high-quality silicone parts used across a range of industries.

Features

Three Configurations

The Babyplast LSR reduces the costs for equipment and moulds. It can be supplied in three different configurations:

- Cartridge system with a premixed 0.5 Kg cartridge.

- Loader mixer system with two 1 Kg cartridges (A+B components).

- Loader mixer system system for two 20 Kg containers (A+B components).

Precision

The Babyplast 6/12 injection molding machine stands out for its unmatched precision, thanks to its cutting-edge injection piston and innovative pre-plastification system. This advanced technology ensures meticulous detail and accuracy in every molding process. The machine’s versatility allows for precise customization, delivering consistent and optimal performance every time. With the Babyplast 6/12, you can expect exceptional quality and precision, making it a leading choice in the injection molding industry.

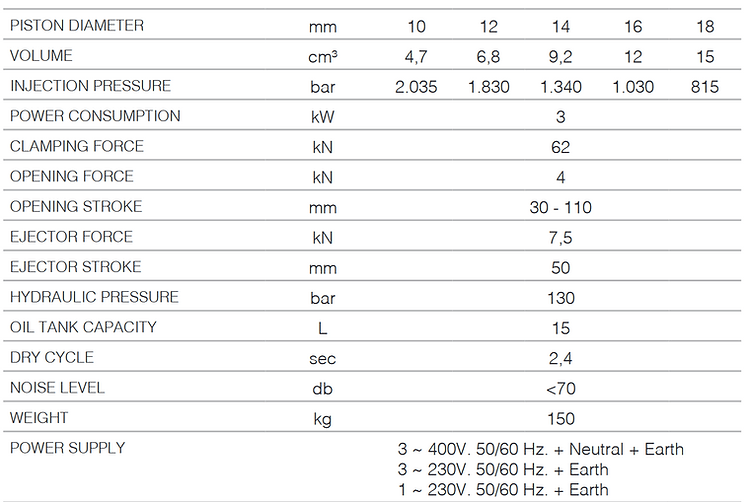

Specifications & Technical Data

- Backlit 8″ colour touch screen LCD

- Vacuum function for the mould

- Cooled machine nozzle with pneumatic shut off valve for direct injection into the part.

- 3 different configurations: premixed 0.5 kg cartridge (A +B components) – loader mixer (1 kg cartridges A+B) – loader mixer (20 kg containers A+B)

- Various different languages can be selected

- Easily accessible pages thanks to multi-function keys

- Quality Control on 4 cycle parameters

- PID temperature control

- 4 temperature control zones with differentiated mould temperature adjustment (moving and fixed half)

- Manages and stores over 1000 production cycles

- Program back-up USB output

- Ethernet Connection : TCP modbus

- Pressure control with electronic transducer

- Injection and clamp position controlled with linear transducers

- Proportional hydraulics

- Very quiet motor pump controlled by an inverter

- Euromap 67 card (optional)

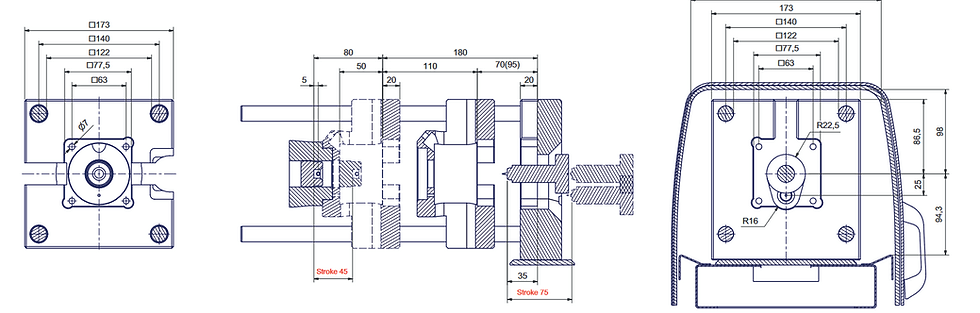

- Savings in the construction of the mould thanks to the machine platens which act as bolsters. Hence only the cavity plates need to be made.

- Low running costs – installed power 3 kW – cooling approximately 120 l/h

- Off centre injection technology – 5 pistons of 3 to 15 cc with 2650 to 815 bar

- Output for auxiliary control

- Cooling circuit (6 zones)

- Temperature tolerance band

- Hydraulic ejector with ejecor return control sensor

- Air blow and core pull control