Micro Optical Moulding

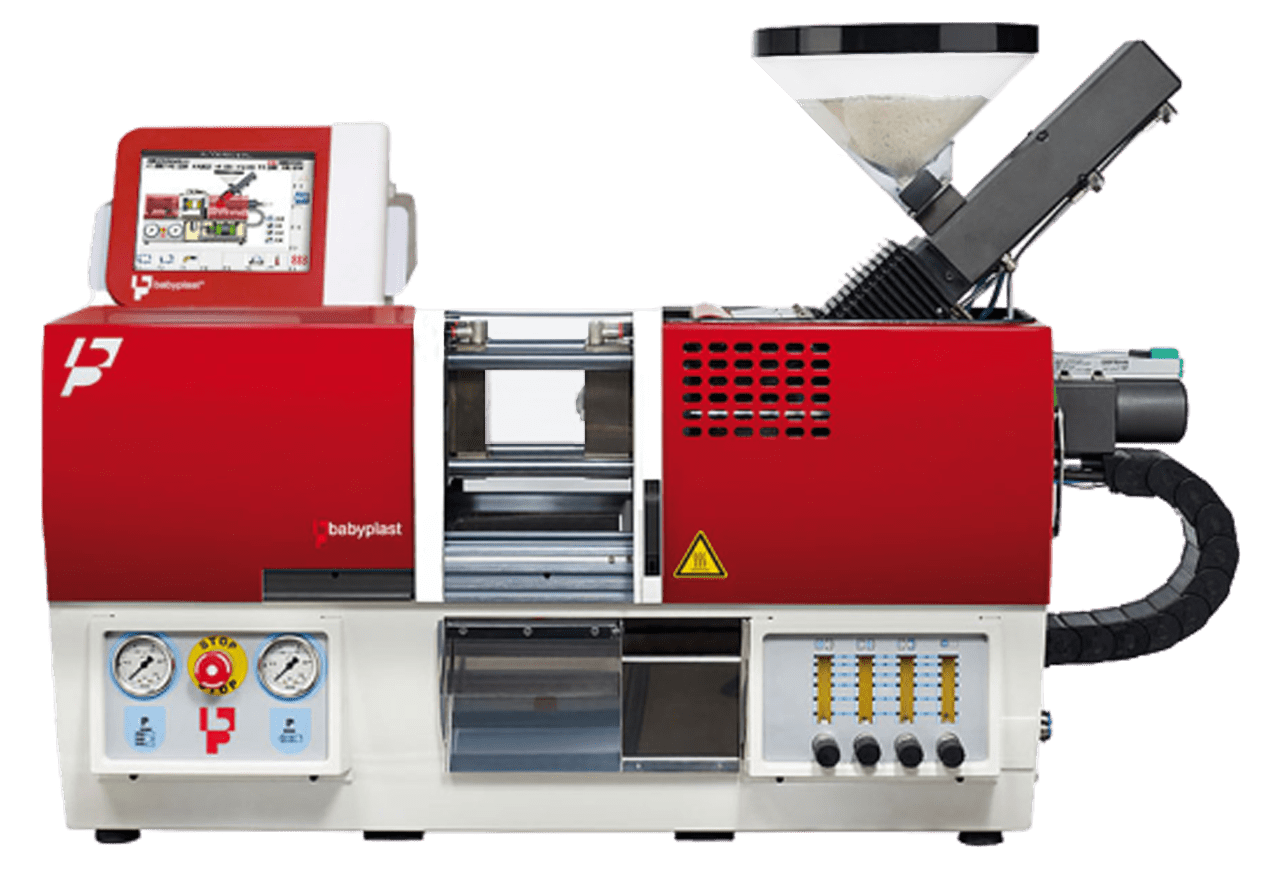

Discover the exceptional capabilities of Micro Optical Moulding, available exclusively through Babyplast UK. From compact, high-precision moulding machines to advanced multi-shot and vertical systems, our technology is designed for accuracy, efficiency, and reliability. Whether you’re producing intricate medical components, automotive parts, or specialist prototypes, our Micro Optical Moulding solutions deliver consistent, high-quality results every time.

Every project has its own challenges. That’s why we offer tailored Micro Optical Moulding configurations to match your production requirements, materials, and budget. Our experts work with you to ensure your system is optimised for performance and long-term reliability.

Discover What Babyplast Can Create

At Babyplast, our innovative micro-moulding solutions enable the production of complex, high-precision parts designed to meet the diverse needs of industries requiring precision-engineered components. Our machines are capable of processing a wide range of materials, including plastics, ceramics, metals, micro materials, and rubber, making them ideal for numerous applications.

Who Uses Babyplast?

Babyplast’s advanced micro-injection moulding technology is renowned for its versatility, making it a valuable solution across a wide range of industries, including Automotive, Medical and Pharmaceutical, Education, Construction, Electrical Goods, Consumer Goods and many more.

As these industries continue to innovate, Babyplast remains at the forefront, offering cutting-edge micro-moulding solutions to meet the evolving demands of modern manufacturing.